racks storage equipment pallet rack logistic rack

Was a month long project and everyone stayed healthy thank goodness. I have been doing this for 8 years and this was the first time I was faced with obstacles like this, we had to work smarter and we finished this job a week ahead of schedule.

racks storage equipment pallet rack logistic rack

New installation in process for a cold storage distribution center in Florida. This project comes with increased difficulty because its a working freezer with customer product still on the rack. We had to take it down and immediately build new rack so they could re-load it and pull their orders at the same time.

| UPRIGHT LOADING TABLE | ||||||||||

| 80x60x1.8 8500KG/BAY | ||||||||||

| 80x60x2.0 9400KG/BAY | 100x70x1.8 11800KG/BAY | |||||||||

| 90x70x1.8 10000KG/BAY | 100x70x2.0 13500KG/BAY | |||||||||

| 90x70x2.0 11800KG/BAY | 100x70x2.3 15000KG/BAY | |||||||||

| 90x70x2.5 15000KG/BAY | 100x70x2.5 16300KG/BAY | |||||||||

| BOX BEAM LOADING TABLE | ||||||||||

| Beam length (mm) | 80*50*1.5 | 100*40*1.5 | 100*50*1.5 | 110*50*1.5 | 120*40*1.5 | 120*50*1.5 | 140*40*1.4 | 140*50*1.5 | 160*40*1.5 | 160*50*1.5 |

| 1500 | 4286 | |||||||||

| 1800 | 2977 | |||||||||

| 1900 | 2672 | 3809 | 4535 | |||||||

| 2200 | 1993 | 2841 | 3382 | 4219 | ||||||

| 2300 | 1823 | 2599 | 3095 | 3860 | 3918 | 4665 | ||||

| 2400 | 1674 | 2387 | 2842 | 3545 | 3598 | 4284 | ||||

| 2500 | 1403 | 2000 | 2381 | 2970 | 3014 | 3598 | 4340 | 5160 | ||

| 2600 | 1297 | 1849 | 2201 | 2745 | 2787 | 3318 | 4010 | 4771 | ||

| 2700 | 1203 | 1715 | 2041 | 2546 | 2584 | 3077 | 3716 | 4425 | 5068 | 6033 |

| 3000 | 974 | 1389 | 1655 | 2065 | 2093 | 2492 | 3010 | 3585 | 4105 | 4887 |

| 3300 | 708 | 1010 | 1202 | 1500 | 1522 | 1812 | 2189 | 2610 | 2985 | 3555 |

| 3600 | 600 | 849 | 1010 | 1260 | 1279 | 1523 | 1839 | 2190 | 2508 | 2986 |

| 3800 | 540 | 762 | 907 | 1135 | 1148 | 1369 | 1658 | 1965 | 2251 | 2680 |

| 4000 | 485 | 687 | 818 | 1024 | 1036 | 1235 | 1550 | 1774 | 2032 | 2419 |

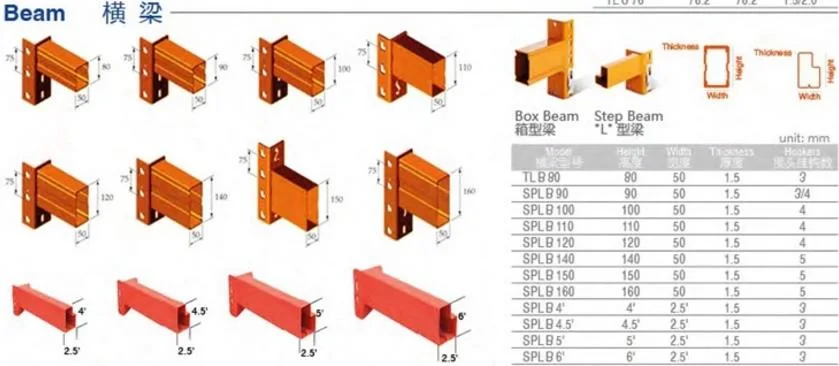

Most common type of racks storage equipment pallet rack logistic rack used in industrial warehouses as it is extremely sturdy and heavy duty. The orange beams are installed together with specially made safety pins to prevent accidental dislodgement of the beams.

Depending on the loading capacity required, different types of beams will be used. Height of each level can also be adjusted according to requirements. Best for goods that are bulky, long and heavy.

Specifications:

Height (mm): 1200 up to 6000 (per 300mm interval)

Depth (mm): 600, 900, 1200

Length (mm): 1350, 1850, 2100, 2450, 2700, 3000, 3300, 3600

Decking Material: Plywood, Metal Shelving, Wire Mesh

Loading Capacity: 1000kg, 2000kg, 3000kg / UDL per level

Colour: Blue frame, Orange beam

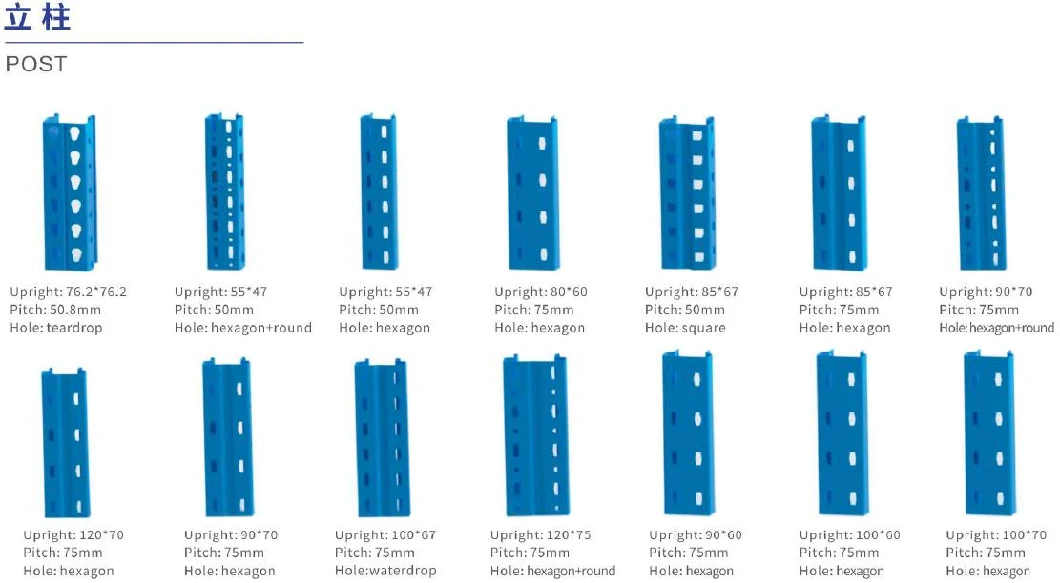

Parts of rack pictures of racks storage equipment pallet rack logistic rack

Company information:

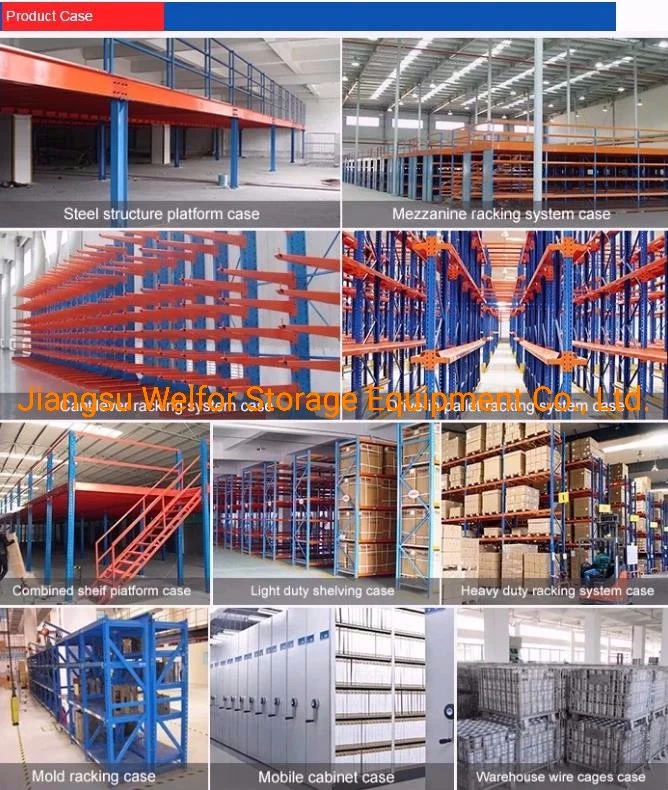

1) NANJING WELFOR Storage Equipment Co., Ltd. is one of the standard large-scale production base that specialized in the R&D, design, manufacture, install and consultation service of storage rack equipment, logistics conveyor systems.

2) The company has strong technical development efforts and product development capabilities, advanced production equipments, mature production technology and perfect quality assurance system.

3)Our company is one of the standard largescale production bases specialized in the R&D, design, manufacture, install and consultation service of storage rack equipment and logistics conveyor systems. Our company has made technical development efforts and we have product development capabilities, advanced production equipment, mature production technology and a perfect quality assurance system.

The working flow of: racks storage equipment pallet rack logistic rack

racks storage equipment pallet rack logistic rack are storage systems composed of frames and beams designed specifically for the efficient loading, sorting and storing of palleted loads. Pallets, which are simply a base made from wood or plastic, are used constantly in the transportation and shipping of products. By providing a uniform base size and shape, products can be stored more effectively.

Pallet racks take into account the size of the pallets and allow for maximum storage capacity by allowing the palleted loads to be stacked vertically and horizontally. Forklifts are often used to move and lift pallets within warehouses and loading facilities. Depending on the ceiling height of a facility, if fork lift trucks are available, pallets can be stored on high reaching racks. The desired accessibility of stored goods will affect the manner in which they are stored. Push back racks are one of the most commonly used type of pallet racking system as they are organized by depth, greatly reducing the required aisle space. The rails of the rack are slightly angled, using gravity to aid in moving the pallet loads and thus reducing the amount of energy required for loading and unloading. Other designs of pallet racking systems will differ depending on the size and shape of the pallet themselves.

Due to the nature of the operation and the typically large and heavy loads on pallets, there are important safety considerations to follow. An important consideration to take into account is the load weight of a particular item and the corresponding required structural strength of its support shelving. Overloading racks or using pallets which are damaged or broken could result in disastrous aspects. In warehouse racking, the safety of personnel working around the storage rack systems, as well as the protection against damage to goods is important. Rails and columns should be secured and made of materials which are strong enough to hold the weight of heavy loads. Further safety measures can be added in the form of wire mesh decking or grids across the racks to increase the strength of the shelving, and to prevent objects falling down. Rollers can also be added to the racks to create rolling racks which further aid in loading and unloading ease. Pallet racks may be purchased new or used. Used racks are a cheaper alternative and for many standard pallet load sizes are more than adequate to meet storage needs. Manufacturing new pallet racks may be necessary however for spaces or loads which require unique dimensions or specifications.

OUR FACTORY

Any questions, please kindly leave us a message, we will reply you within 5 minutes from Monday to Friday, within 1 hour during weekend and holidays.

By Sunny Wang---The Sales Manager